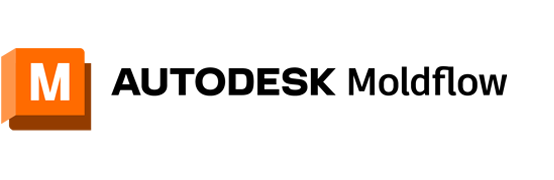

Autodesk Moldflow software provides fast, accurate and flexible injection moulding simulation tools to help analysts, designers and CAE engineers validate and optimise plastic parts and moulds.

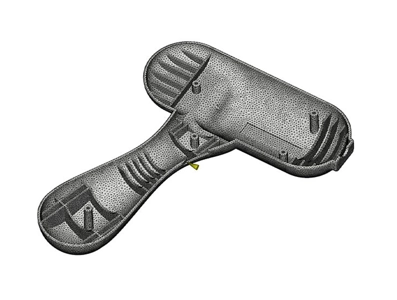

The simplified, user-friendly interface enables even non-expert users to read and interpret simulation results easily. Moldflow makes it possible to predict up to 90% of possible defects on products such as joint lines, air bubbles, suction marks, shrinkage and deformation of components.

With advanced simulation tools, you can manufacture innovative products more quickly, reducing the number of expensive physical prototypes and avoiding potential manufacturing defects.

Autodesk Moldflow supports direct data exchange with most CAD software tools, reading native formats on import. Thanks to direct integration with Fusion 360, it is possible to make rapid changes to the geometry, and perform validation and modelling checks to simplify the analysis setup.

Find out how Moldflow revolutionised their business processes

"Autodesk Moldflow has allowed us to determine the correct positioning of the injection points, so as to ensure that the part was properly filled."

Click below to know the full potential of this technology

Find out how 3D technologies revolutionised their business processes

CAD & CAM software for engineering, design and product analysis.

Find out more

Find out more

Advanced CAM software for complex, high-speed CNC machining

Find out more

Find out more

Set of professional tools for product development and production planning

Find out more

Find out more

Mechanical design, documentation and product simulation.

Find out more

Find out more

Want to know more about Moldflow? Fill in the form below. You will be contacted as soon as possible by one of our experts.