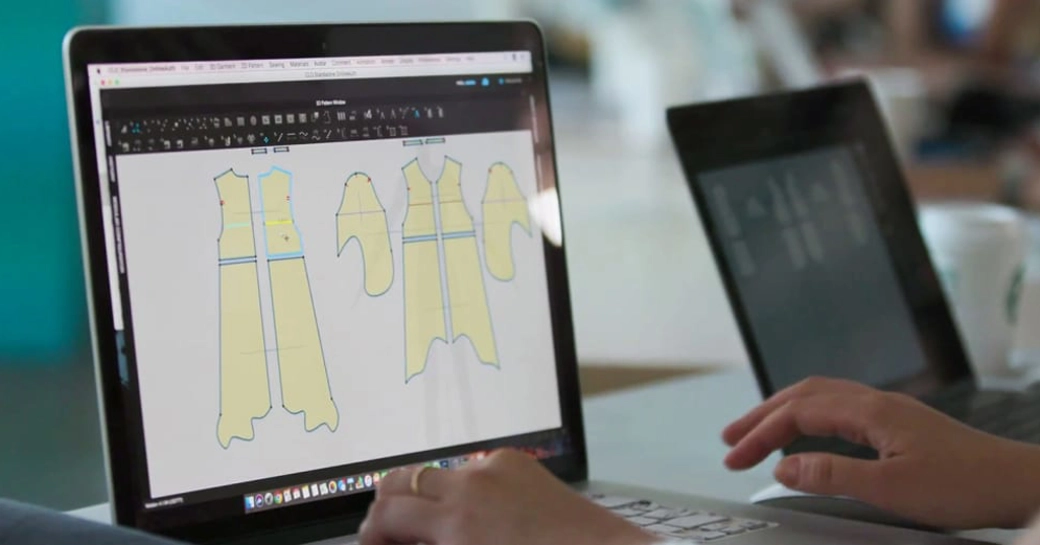

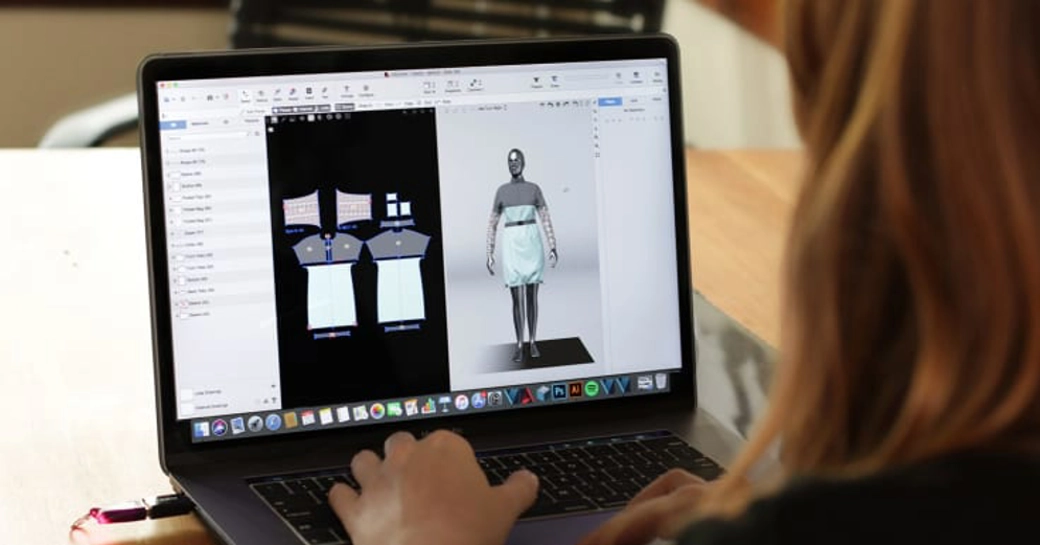

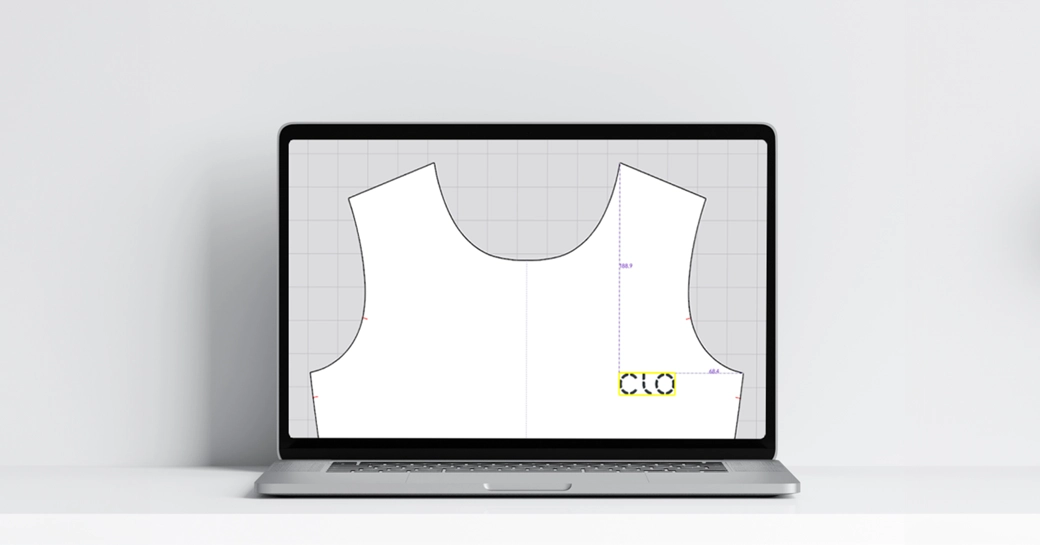

With CLO, fashion companies can revolutionize their entire product development process. CLO allows to design 3D garments, bags and accessories, reducing prototyping time and costs.

The adoption of CLO and digital tailoring has proven to be crucial for companies that are developing strategies based on sustainable choices, geared to reduce the waste of materials and energy resources.

Thanks to the fabric simulation tool, any type of material can be accuretely reproduced in 3D.

CLO also integrates with the xTex Vizoo scanning solution and the Adobe Substance 3D suite for digitizing materials or textiles.

For many years now, Prisma Tech has been a partner of CLO Virtual Fashion and the exclusive dealer of CLO in Italy.

Thanks to its technical team, Prisma Tech can develop the most appropriate work process together with the customer, so as to achieve the set goals.

Thanks to partnerships with top design institutes, we also help schools train the professionals of the future (such as the 3D fashion designer, the VR specialist and the Virtual visual merchandiser). With state-of-the-art tools and the support of experts with years of experience in the implementation of 3D technologies, we have the capacity to develop the skills needed to meet the challenges of the fashion industry.

Find out how CLO revolutionised their business processes

Click below to know the full potential of this technology

Find out how 3D technologies revolutionised their business processes

Fashion

12/10/2020

Moda,Design

12/10/2020

Fashion

08/10/2020

Fashion

08/10/2020

Fashion

30/09/2020

Fashion

28/09/2020

Fashion

31/03/2020

Fashion

06/10/2020

Fashion

07/02/2023

Fashion

05/03/2023

Fashion

18/05/2023

Fashion

29/06/2023

Fashion

14/07/2023

Fashion

16/10/2023

Fashion

21/02/2024

Fashion

02/04/2024

Fashion

27/05/2024

Fashion

18/06/2024

Fashion

21/05/2025

ICad3D+ is the first software for footwear design and pattern engineering that integrates two different environments into a single program, 3D design and 2D patterns.

Find out more

Find out more

Adobe Substance 3D is a software package that allows you to create materials from scratch or make changes to existing ones.

Find out more

Find out more

Photorealistic 3D visualisation and virtual reality for the review and presentation of prototypes

Find out more

Find out more

CAD & CAM software for engineering, design and product analysis.

Find out more

Find out more

The ultimate material scanner.

Find out more

Find out more

We Wear offers technological solutions for size recommendation and virtual fitting.

Find out more

Find out more

Increase sales and improve users' shopping experience through customized product configuration.

Find out more

Find out more

Want to know more about CLO? Fill in the form below. You will be contacted as soon as possible by one of our experts.